DELTA GAS SERVICE SRL

BOURDON TUBE PRESSURE GAUGES, WITH GLYCERINE FILLING

BOURDON TUBE PRESSURE GAUGES, WITH GLYCERINE FILLING

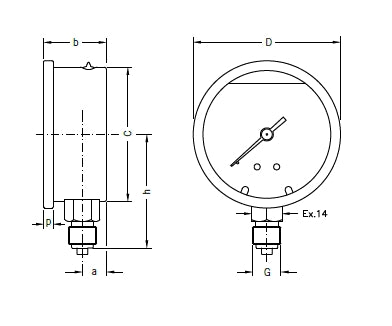

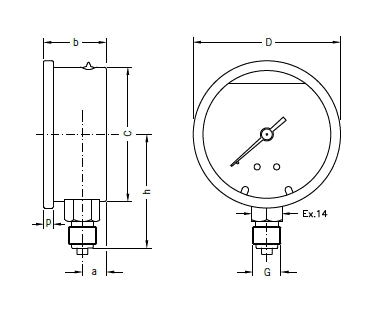

radial connection, DN 63-100 (mod. MG 63-100 RA)

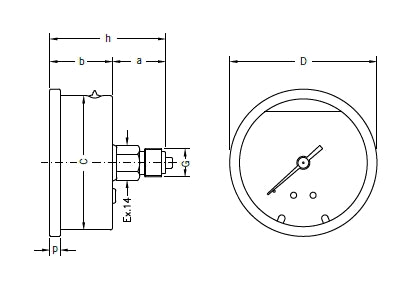

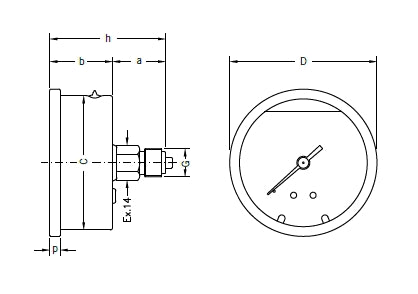

rear connection, DN 63 (mod. MG 63 PA)

DIMENSIONS AND WEIGHTS

|

MOD. |

D |

G |

C |

to |

b |

h | p | WEIGHT |

| MG 63 RA | 68mm | G 1/4" | 62mm | 11mm | 29mm | 53mm | 5mm | 203 g |

| MG 100 RA | 105mm | G 1/2" | 99mm | 12.5mm | 33mm | 84mm | 5mm | 575 g |

| MG 63 PA | 68mm | G 1/4" | 62mm | 24mm | 29mm | 53mm | 5mm | 216 g |

APPLICATIONS

Manometers particularly suitable for measuring

pulsating, rapidly fluctuating pressures, or in the presence of

vibrations. Shock resistant. Suitable for all liquid fluids

or gaseous as long as they are not highly viscous, crystallizing or

corrosive for copper and tin alloys

MAIN SECTORS OF USE

- hydraulics (systems and equipment)

- technical industrial equipment

- pressure washers

- agriculture and livestock farming

- means of transport

- compressors

REGULATORY REFERENCES

- EN 837-1

accuracy class 2.5

- EC directive 2014-68 PED (if full scale <200 bar)

- degree of protection IP65 according to EN 60529

LIMITS OF USE

Temperature

On the body of the pressure gauge -40 ÷ +70 °C

Fluid under pressure max 90 °C

Pressures

Up to 3/4 of full scale value for static pressures

Up to 2/3 of full scale value for fluctuating pressures

Up to full scale value for short periods

Fluids

Liquids or gases not corrosive to copper alloys, not

crystallizing, not highly viscous

Not suitable for oxygen

CONSTRUCTION FEATURES

- polished AISI 304 stainless steel case

- glass retaining ring in polished AISI 304 stainless steel

stapled to the case with a gasket for watertightness

- shatterproof polycarbonate glass

- filling liquid: 99.7% bidistilled glycerine

- white dial in pre-painted aluminum

- two-color graphics: double bar scale (in black) + psi

(in red)

- aluminum index

- brass fitting

- "C" shaped Bourdon spring in copper alloy for pressures of

full scale up to 40 bar, bronze spiral spring

phosphorous for higher pressures

- High sensitivity movement in brass alloy watchmaking

(OT59)

- welding: in tin alloy up to 40 bar, in alloy

silver for higher pressures

Couldn't load pickup availability